Description

| VMU310 Video Measurement Unit (Caliper) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The VMU310 has been replaced by the VMU250. Please contact MicroImage Video Systems for more information. The VMU250 is in full production. See VMU250

New Features:

These features are standard numbers 31032, earlier units can be factory upgraded with the ratio display and widescreen correction features. The VMU310 has an extensive array of standard features which include:

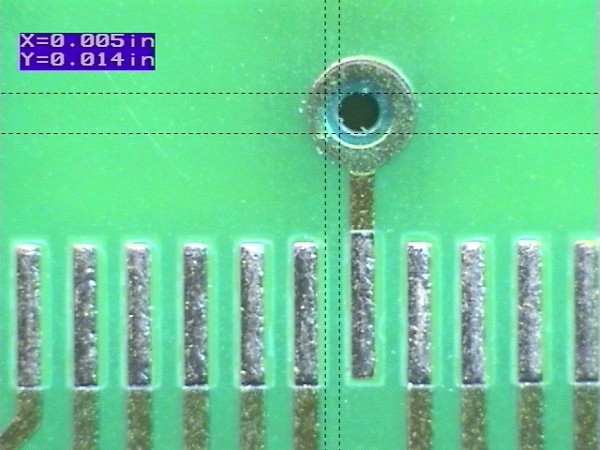

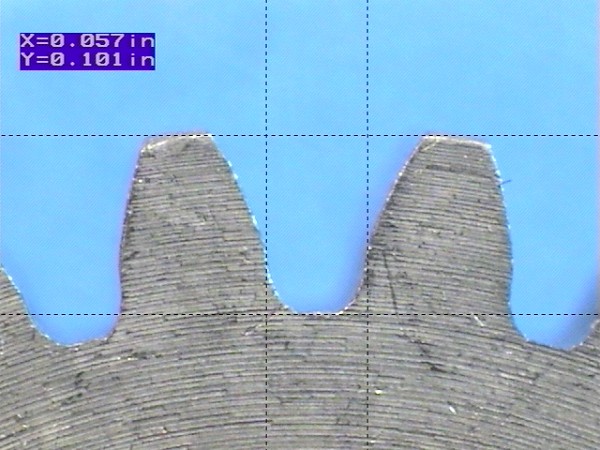

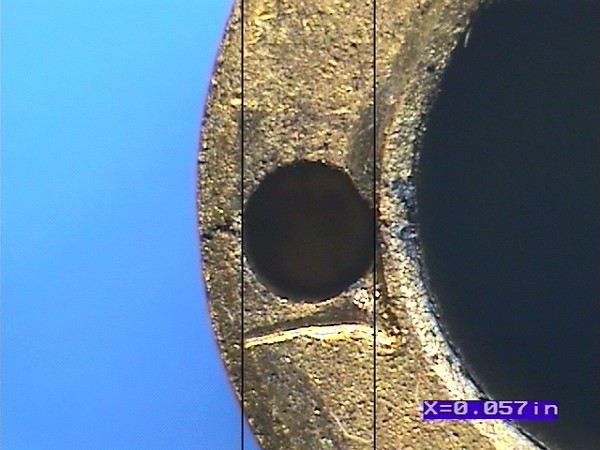

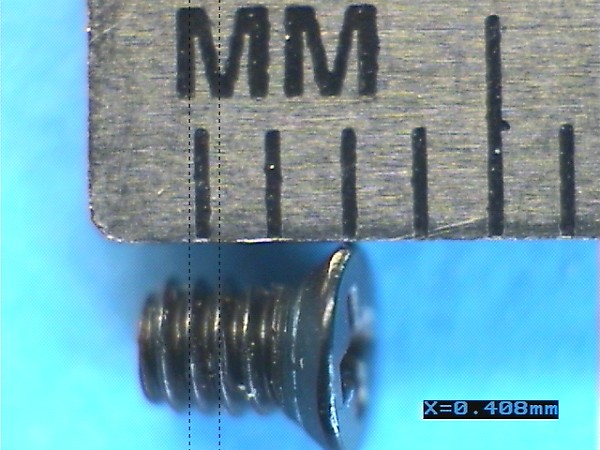

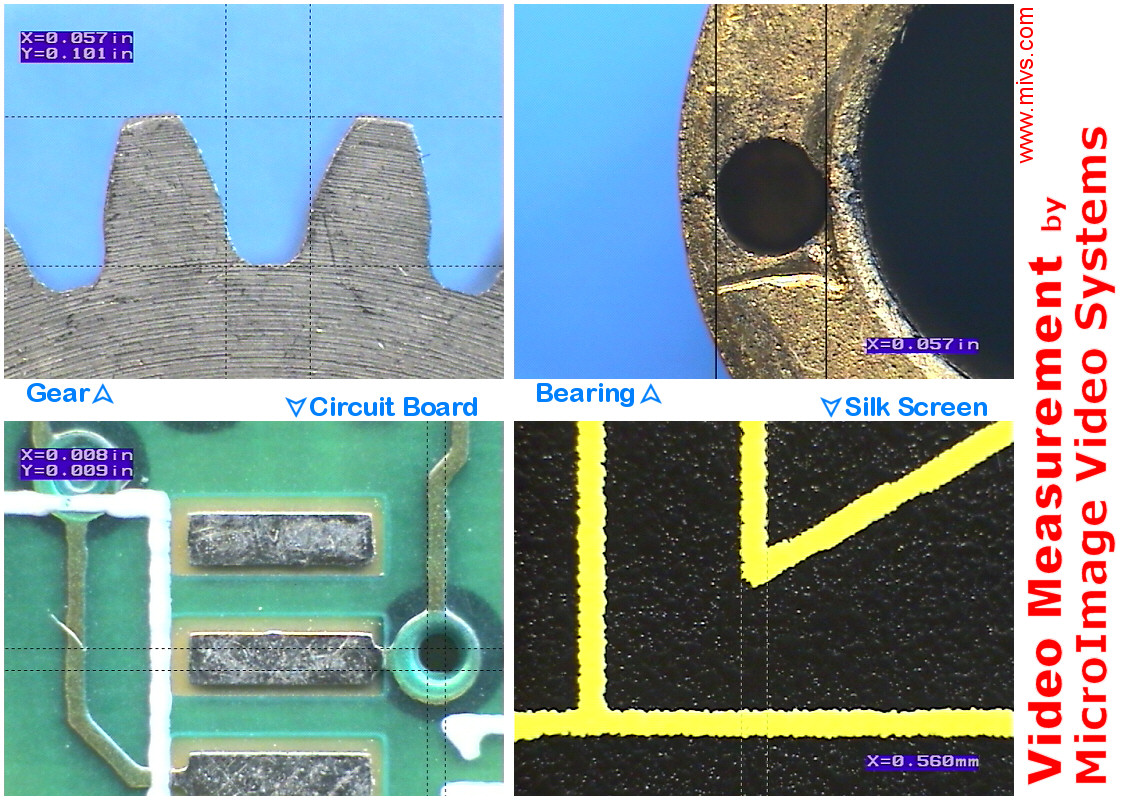

The VMU series of video calipers from MicroImage Video Systems utilize extensive digital processing to maintain high accuracy and repeatability. Usable with most video standard definition video cameras, the VMU310 provides fast, efficient and affordable non-contact measurement. Units are compatible with NTSC/PAL/RS170 and CCIR video standards. The MicroImage VMU series of video measurement units are designed to be highly flexible and powerful, yet easy to use. Unlike analog based units, all mathematics are done digitally, allowing the VMU series to maintain consistent precision regardless of the scale factor. All lines are digitally rendered for solid, repeatable performance over time with virtually zero drift. High precision optical encoders are used for the position controls, eliminating jitter which can plague analog based measurement devices. VMU310 units support both NTSC and PAL (as well as the common B&W RS170 and CCIR) video standards. The units will automatically detect the signal and adjust accordingly. S-Video signals are recommended over composite video for the highest performance. Using the VMU is easy. A size reference is placed in the field of view and the cursors are moved to the reference dimensions. The calibration value is entered on the keypad and can be set to the X or Y axis. This provides far more range and precision than using a rotary control to set calibration. From this point on, the unit is calibrated, provided the distance to the object or magnification (zoom) doesn’t change. Nine memories are provided to store multiple calibrations for different optics/magnifiers, saving significant time. In addition, each memory can be labeled to make recall easier. The units remember all settings in non-volatile memory when turned off. The readout display can be moved virtually anywhere on the screen. Any combination of x, y, diagonal, H/V ratio, V/H ratio measurements plus time and date can be displayed at the same time. The number of displayed digits can be limited to make reading easier in some applications. The color and background of the numeric display can be changed while the lines can be changed from black to gray to white with a front panel switch. Any line can independently be turned off, displayed as solid, or set to several different serrated effects for better visibility. A number of additional features have been added to simplify day to day usage. Cursors may be moved fully independently, may be moved in pairs where one control moves both cursors on the same axis and the second control changes the spacing between them or use mirror movement where one control moves both lines and the other control adjusts the separation based on the center point between them. Each control may be independently locked to avoid inadvertent adjustment and there are separate locks for the X and the Y movement. Controls can also be independently locked from within the menu system, regardless of the state of the lock button as further protection against accidental change. The lines may be displayed full screen or can be displayed as a box on screen. A front panel bypass switch allows the user to quickly turn the line and readout display off or on as needed. All VMU series products can be powered from a clean +12VDC, negative ground power source. A serial remote option is also available for use with automated systems. Contact MicroImage Video Systems for units that work with RGB Video signals. For OEM applications, MicroImage Video Systems can provide board level product, private labeling or even custom functions. The units are based on a new MicroImage Video platform which is highly flexible and programmable. All units carry a one year parts and labor limited warranty. At MicroImage Video Systems we incorporate suggestions from customers when possible. Several customers suggested password protection so that calibration settings could not be changed. We added this capability to all production units with several levels of password protection. It also has a programmable auto time out feature. In the event a key is not pressed within a certain amount of time, the protection is automatically re-enabled. This is important in case it becomes forgotten after a setting is changed. Password protection can also be disabled for easy access in a safe environment. An internal RS232 connection is present for custom and OEM applications. This allows for complete control of the VMU from a host. The port uses the MicroImage Control Protocol. Note that this port does not go to an external connector. Contact MicroImage Video Systems for this option. The VMU310 improves on the VMU300 with digital processing and a wider range of calibration values, named memories and much more. The VMU310 uses very high quality, sealed optical encoders. The VMU310 is RoHS compatible and utilizes lead-free processing. The VMU310 is available packaged (cased) or as a board level product for OEM applications. Power is provided by a universal wall plug power supply (included with cased products) or it can be operated from +12VDC (negative ground). Board level products do not include the power supply and a 12VDC power source must be provided. The unit is packaged in a durable metal enclosure. Board Level, OEM and Custom products are also available. Please contact MicroImage Engineering for additional information. The VMU310 has a one year parts and labor limited warranty.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||